Production Process

Standard Process

Computer-to-Plate (CTP)

The first step in our printing process is to send the company’s design from our software to the CTP machine. This is when the image is transferred from a computer file to a printing plate.

Printing

The plate(s) is then transferred to the adequate printing machine in our facilities to transfer the image on carton. We have a range of printer options that depend on the amount of colours involved and other technical criteria.

Varnishing

The plate(s) is then transferred to the adequate printing machine in our facilities to transfer the image on carton. We have a range of printer options that depend on the amount of colours involved and other technical criteria.

Die Cutting

A customized steel die board is then used to direct the die cutting machine to cut and outline the carton, as per each product’s unique specs, before being handed over to take away the paper waste.

Folding and Gluing

The last step in our standard printing process is to place the carton sheet in our folding and glueing machines to form the three-dimensional shape we are all accustomed to see. The products all remain flat, however, until they’re packed…

Metalized&Special effects

Metalized

These are polymer films coated with a thin layer of metal, usually aluminium, and they offer a shiny look to the package. We use it with premium products and ones that are looking to stand out.

Hot Stamp

This is a dry printing method in which we heat the die on a plate and we place the product we want to stamp beneath it. We then insert a metalized carrier between the two and we press the die…

Plastic Paper Coating

We coat certain products with a laminated composite material made of paper with a plastic-treated surface. This effect has a functional purpose like improving the product’s water resistance, tear strength, scratch resistance, and its ability to be heat sealed.

Embossing

We create raised images and designs against the product’s backgrounds using two dies: a raised one and a recessed one. The dies fit into each other so that when the paper is pressed between them, the raised dies forces the…

Spot UV

We tactfully add a glossy coating to a specific area of the product to highlight it in contrast with the rest of the body. This effect draws the viewer’s attention to a certain part of the design and gives it…

Hologram

This is a highly technical process that gives a three dimensional effect by scattering reflected light and diffracting it using laser technology. We apply it to select products upon request for its premium feel and as an anti-counterfeit measure for…

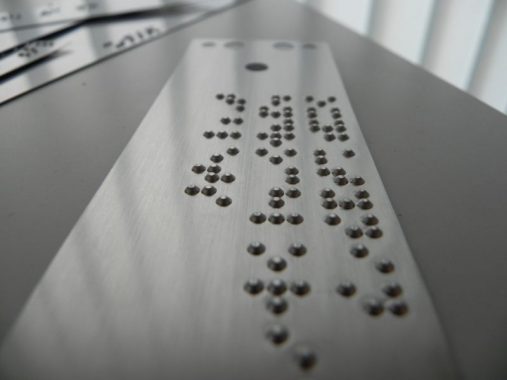

Braille

We use a braille embosser to produce tactile braille cells on our products upon request.

Printing Leaflets

Printing

Upon sending the design to the printing plate, we start by printing the leaflets on paper in compliance with each clients specifications and material requirements.

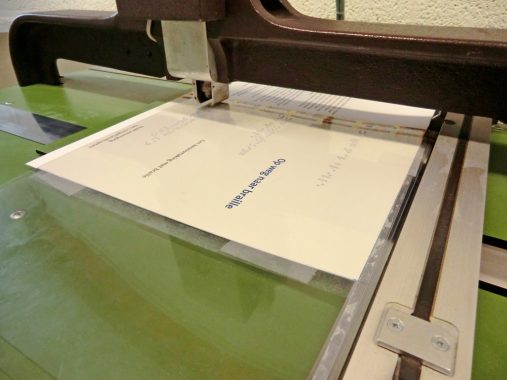

Cutting

The paper is then moved to the cutting station where our heavy-duty guillotine paper cutter is skillfully operated.

Folding

After being cut to spec the leaflets are fed into a folding machine that gets them to their final shape as per the client’s requirements.

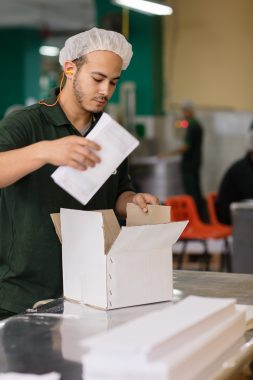

Packing

The last step is to stack the leaflets together in their designated packages before sending them off for quality inspection and shipment.